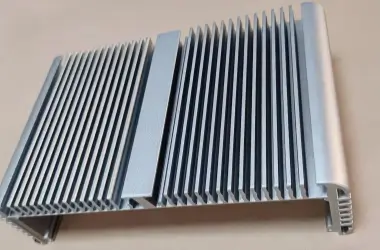

Anodizing

Anodizing is an electrochemical process that enhances surface durability and corrosion resistance. We offer anodizing for aluminum, stainless steel, magnesium, and titanium, providing a sleek, matte or glossy finish ideal for both functional and decorative purposes.