Practical Tips for Self-clinching Fastener in Sheet Metal Fabrication

Self-clinching fasteners are common in sheet metal fabrication. They allow thin metal parts to be joined in a strong and reliable way without welding. The process is pressing a fastener, such as a stud, nut, or standoff, into the prepared hole of sheet metal parts. After pressing, it becomes a permanent part of the sheet metal panel, and provides reusable threads or mounting points.

How do Self-clinching Fasteners Work?

Self-clinching Fasteners have the advantages of axial and torsional resistance, load capacity, and durability characteristics. Generally speaking, the material of fasteners is harder than that of the sheet metal part. For example, aluminum sheet metal parts use steel or stainless steel self-clinching fasteners, while steel sheet metal parts use stainless steel rivets, etc. Below is a list of common fasteners in different materials and their properties

Most of the time, doing a surface treatment on parts for both aesthetics and protection. According to our experience, most of our customers choose anodizing for aluminum sheet metal parts, while steel and stainless steel parts are typically powder-coated, painted, or black oxide. Some surface treatments involve chemicals, so we often process press riveting after surface treatment. In this case, rivets keep their color.

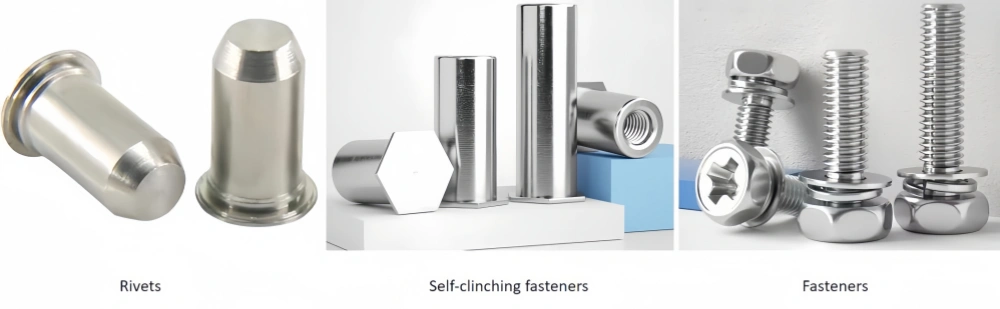

The Differences Between Self-clinching Fasteners, Rivets, and Fasteners

Self-clinching fasteners, rivets, and fasteners all of them serve to join components. However, the working principle is different.

Self-clinching fasteners are pressed into thin sheet metal parts under pressure machines. Good choice for precision thin sheet metal parts (0.7mm- 3mm) assemblies.

Rivets is a permanently joined material by deforming their tails to lock sheet metal parts together, to create high strength feature, but can not be disassembly any more.

Fasteners is a wide of term, which includes screws, bolts, nuts, rivets, and self-clinching parts etc. In terms of expression, any component that mechanically joins two or more parts is called fastener.

Applications of Self-clinching Fasteners in Sheet-Metal Parts: Prototype and Batch Production

Self-clinching fasteners are widely used in sheet metal parts, where shelling house or parts need threaded holes, without welding. In the prototype step, they help engineers validate the structure of the drawing design. Due to the fastener being pressed into a pre-punched hole, the joint remains smooth on the two sides, making it suitable for electronics enclosures, consumer brackets, and industrial housing repeated testing. Self-clinching studs, nuts, and standoffs allow multiple components to be installed and removed without damaging the sheet metal part.

This is very useful when development teams need to adjust dimensions, replace parts, or change the design of layouts during the testing stages.

In small-volume production, automated presses keep the alignment of the holes consistent.

Because the fastener material is harder than the sheet metal, the screws can be put in or taken out more easily. At the same time, it also ensures reliable strength in a long life use.

In industrial areas, such as electronics, communication equipment, and machinery often rely on this technique for this sheet metal parts of thin-wall structures.

Case Study: Sheet Metal Parts with Self-clinching Fasteners

Sheet metal fabrication in Xinprototype shop, self-clinching fasteners are play a key role in thin panels, when traditional threaded holes or welding is impractical.

This case is a small sheet metal part made of a 2 mm aluminum sheet. It’s too thin to make threaded holes. Therefore, after laser cutting and do surface finished, install stainless steel blind hole hexagonal standoffs instead. The hexagonal head is pressed into the preset hole of the thin plate by a pressing machine, causing plastic deformation around the hole. The deformed part is squeezed into the back groove of the self-clinching nut column, so that the self-clinching nut column is riveted to the thin plate, thereby forming a fixed internal thread on the thin plate. We are able to use a screw to install with other components when assembling.

Finally, we got a lightweight but also durable enclosure part. Without damaging the metal sheet face. Compared with welding or riveting, self-clinching fasteners not only improve appearance but also save production time and avoid heat distortion.

How to Pick the Right Type of Self-clinching Fastener for Sheet-Metal Parts?

It has many types of self-clinching fasteners in the markets, selecting the suitable one is important for sheet-metal parts assemblies. Because different fasteners have different functions. Choosing the proper one can ensure the strength and long-term life of the parts.

Self-clinching nuts are ideal for the parts where internal threads are required. The thickness is as low as 0.8mm can be done as wel. Such as mounting covers, etc. The traditional tapping thread holes are not available.

Self-clinching studs provide external threads for installing components. Suitable for PCB boards, electronic panels, appliance manufacturing, or other hardware parts. They eliminate loose screws on the back side of the sheet and keep the smooth surface.

Self-clinching standoffs are good when two panels must be spaced at a distance. Usually, it is used for electrical housings where clearance or airflow is required.

The raw material of the self-clinching fastener is also important. Harder fasteners are often pressed into softer sheet metal so the clinching ring can embed securely.

A practical tip is to confirm the size of the hole in sheet metal part, and consider the thickness of the sheet, pick the right fastener material and type before sheet metal fabrication. If proper choose, self-clinching fasteners create clean, reusable joints without welding.

| Type of Material | Properties | Typical Applications |

|---|---|---|

| Steel | High strength, good wear resistance, cost-effective; zinc plating to prevent rust. | General industrial manufacturing use. |

| Stainless Steel (304 / 316) | Excellent corrosion and heat resistance; long service life in harsh environments. | Marine, chemical, high-quality equipment. |

| Aluminum Alloy | Lightweight with good corrosion resistance. | Aerospace, automotive, consumer electronics. |

| Brass | Excellent conductivity, easy to machine, good corrosion resistance. | Electrical and electronic assemblies requiring stable connections. |

| Special Alloys (Titanium, Nickel, etc.) | Extremely high strength; outstanding temperature and corrosion resistance. | Aerospace, nuclear, power generation, specialized engineering fields. |

Conclusion

Self-clinching fasteners enable thin sheet metal parts to have a threaded joint feature. And improving assembly strength. This is a one of the big technologies to valuable in prototype samples and batch production.

At Xinprototype factory, we work with aluminum, stainless steel, steel, and brass sheet-metal fabrication parts. Also, provide installation of self-clinching fasteners according to our customer drawings. No matter whether prototypes or low-volume.

If you have a project request for sheet metal parts with self-clinching fasteners. Or need support with design or manufacturability checks, our team is always happy to assist.